Mishiinka Buuxinta Saliida La Cunyo ee Dijitaalka ah oo Toos ah

Sharaxaada

Sharaxaada

Buuxinta alaabta saliidda, oo ay ku jiraan saliidda cuntada iyo saliidda warshadaha.Saliidda cuntadu waa tiirka dhaqaalaha qaranka, waa mid ka mid ah cuntooyinka ugu muhiimsan ee nolol maalmeedkeena, sida saliidda lawska, timirta, saliidda la isku daray iyo wixii la mid ah.Saliidda warshadaha ayaa inta badan saliidda saliidda, heerka sare ee otomatiga warshadaha ee maanta, dhammaan noocyada qalabka farsamada ma shaqeyn karaan iyada oo aan saliid lahayn, isticmaalka aad u ballaaran.

Buuxinta alaabta saliidda waxay u baahan tahay saxnaanta buuxinta sare iyo xaaladaha fayadhowrka, taas oo sahlan in loo hoggaansamo dusha qaybaha oo keena qulqulo.Si loo xalliyo dhibaatooyinkan, mashiinka buuxinta saliidda ee GEM kaliya ma dammaanad qaadayo shuruudaha buuxinta, laakiin sidoo kale waxay wanaajisaa dhibaatooyinka daadinta fudud.

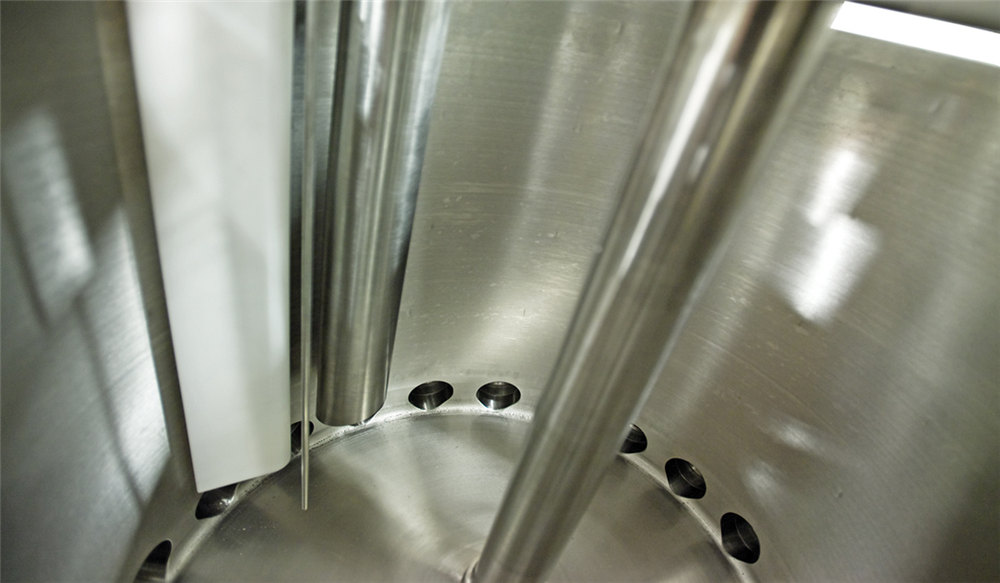

Mawduucyada aadka u sarreeya ee alaabta saliidda awgeed, isticmaalka tuubooyinka farsamada caadiga ah waxay sababi doontaa xannibaadda tuubada soo laabata, markaa mashiinka buuxinta saliidda wuxuu caadi ahaan qaataa habka buuxinta tirada plunger.Mabda'a habka buuxinta tirada plunger waa in walxaha ku jira dhululubada cabbiraadda, buuxinta dhululubo, buuxinta dhalada saddex weel ay si joogto ah u beddelaan, qulqulaan.Jidhka waalka wuxuu u dhigmaa waalka saddex-geesoodka ah.Marka waalka la xiro, dhululubo iyo dhululubo waa la isku xiraa, walxaha waxaa lagu nuugaya dhululubada by piston.Istaroogga piston-ka ayaa go'aamiya mugga walxaha la nuugo, sidaas awgeedna go'aaminta mugga walxaha la buuxinayo.Marka waalka la furo, dhululubada iyo dhalada ayaa isku xiran, shayga la nuugo dhululubada ayaa lagu cadaadiyaa dhalada si loo dhamaystiro habka buuxinta tirada.Maadaama awoodda buuxinta la beddeli karo iyadoo la hagaajinayo istaroogga piston, way fududahay in la buuxiyo dhalooyin awoodo kala duwan leh.Intaa waxaa dheer, qaybta gacanta ku haysa piston-ka waxaa lagu bedeli karaa servo drive, taas oo buuxinta ka dhigaysa mid sax ah iyo awoodda mid ku habboon.

Marka laga reebo buuxinta plunger, badi mashiinnada buuxinta saliidda waxay isticmaalaan tignoolajiyada buuxinta miisaanka.Ka dib marka la go'aamiyo miisaanka madhan ee weelka, tuubada buuxinta ayaa la furayaa marka dhalada la ogaado.Inta lagu jiro buuxinta, dareemaha miisaanku waxa uu ogaanayaa cadadka alaabta la duray.Marka miisaanka loo baahan yahay la gaaro, valve si dhakhso ah ayuu xiraa.Muddo yar oo nasasho ah ka dib, dib u eeg miisaanka.Wax yar ka hor inta aanad gaadhin shaagagga dhalada, tuubada ayaa mar kale kor loo qaadayaa si loo hubiyo in dhaladu ay si nadiif ah uga baxdo mishiinka.Habkan buuxinta waxaa lagu habeyn karaa shaqo toos ah oo CIP ah, nadiifinta koob been abuur ah oo si toos ah loogu rakibay, CIP uma baahna hawlgal gacanta ah.

Tilmaamaha Qaab-dhismeedka Farsamada

1. Buuxinta caadiga ah iyadoo la adeegsanayo buuxinta tirada plunger, buuxinta saxnaanta waa sarraysaa, fududahay in la beddelo.Waalka buuxinta miisaanka elektaroonigga ah/magnetic flowmeter-ka waxaa loo isticmaalaa alaabooyinka leh shuruudo awood sare leh.Si kasta oo ay tahay nooca waalka buuxinta ayaa si wax ku ool ah uga hortegi kara dareeraha waalka.

2. Nidaamka xakamaynta ee Siemens ayaa la qaatay, oo leh awood sare oo toos ah, dhammaan qaybaha shaqadu si buuxda ayey u shaqeynayaan, wax hawlgal ah looma baahna ka dib bilawga (tusaale: xawaaraha buuxinta wuxuu raacayaa xawaaraha xariiqda oo dhan, ogaanshaha heerka dareeraha, nidaamka qaadashada dareeraha. , nidaamka saliidaynta, habka gudbinta koofiyadda dhalada)

3. Gudbinta mishiinku waxay qabataa nashqad qaabaysan, isbedbeddelka soo noqnoqda ee nidaamka xawaaraha stepless, nidaaminta xawaaraha ballaaran.Darawalku waxa uu ku qalabaysan yahay qalab dufan si toos ah u saliidayn kara, kaas oo keeni kara saliid goob kasta oo saliidaynaysa iyadoo loo eegayo baahida wakhtiga iyo tirada, oo leh saliid ku filan, hufnaan sare, buuq yar iyo cimri dheer.

4. Dhererka walxaha ku jira dhululubada buuxinta waxaa lagu ogaadaa baaritaanka elektiroonigga ah, iyo PLC-ga xiritaanka PID-da ayaa hubiya heerka dareeraha xasilloon iyo buuxin la isku halleyn karo.

5. Marka loo eego shuruudaha alaabada kala duwan, habka buuxinta iyo nooca xiridda ayaa la isku waafajin karaa marka la rabo.Habab kala duwan oo wax lagu xidho ayaa la heli karaa (tusaale, qanjidhada balaastikada, koofiyada dunta caaga ah, iwm.)

6. Kanaalka walxaha si buuxda ayaa loo nadiifin karaa CIP, iyo goobta shaqada iyo qaybta xiriirka dhalada si toos ah ayaa loo dhaqi karaa, taas oo buuxinaysa shuruudaha nadaafadda ee buuxinta;Waxaa loo isticmaali karaa iyadoo loo eegayo baahida miiska janjeera ee hal dhinac ah;Koobab been abuur ah oo toos ah oo CIP ah ayaa sidoo kale la heli karaa.

7. Wax xiriir ah oo ka dhexeeya dhalada iyo shayga buuxinta ma jiro inta lagu jiro buuxinta si looga fogaado wasakheynta.

Qaab dhismeedka

Halbeegga

| Maya | Taxanaha Model | Material Viscosity CPS | awood | Ku qalabaysan isha hawada | Ku qalabaysan il koronto | Dhererka khadka gudbinaya

| ku haboon nooca dhalada |

| 01 | JH-OF-6 | 0-200 | 3Kw | 5-6bar | 380V | 1000± 50mm | Lagu habeeyey iyadoo loo eegayo baahida macaamiisha

|

| 02 | JH-OF-8 | 0-200 | 3Kw | 5-6bar | 380V | 1000± 50mm | |

| 03 | JH-OF-10 | 0-200 | 3.5KW | 5-6bar | 380V | 1000± 50mm | |

| 04 | JH-OF-12 | 0-200 | 3.5KW | 5-6bar | 380V | 1000± 50mm | |

| 05 | JH-OF-14 | 0-200 | 4.5Kw | 5-6bar | 380V | 1000± 50mm | |

| 06 | JH-OF-16 | 0-200 | 4.5Kw | 5-6bar | 380V | 1000± 50mm | |

| 07 | JH-OF-20 | 0-200 | 5Kw | 5-6bar | 380V | 1000± 50mm |