Mashiinka Buuxinta Daasadaha Wareega

Video

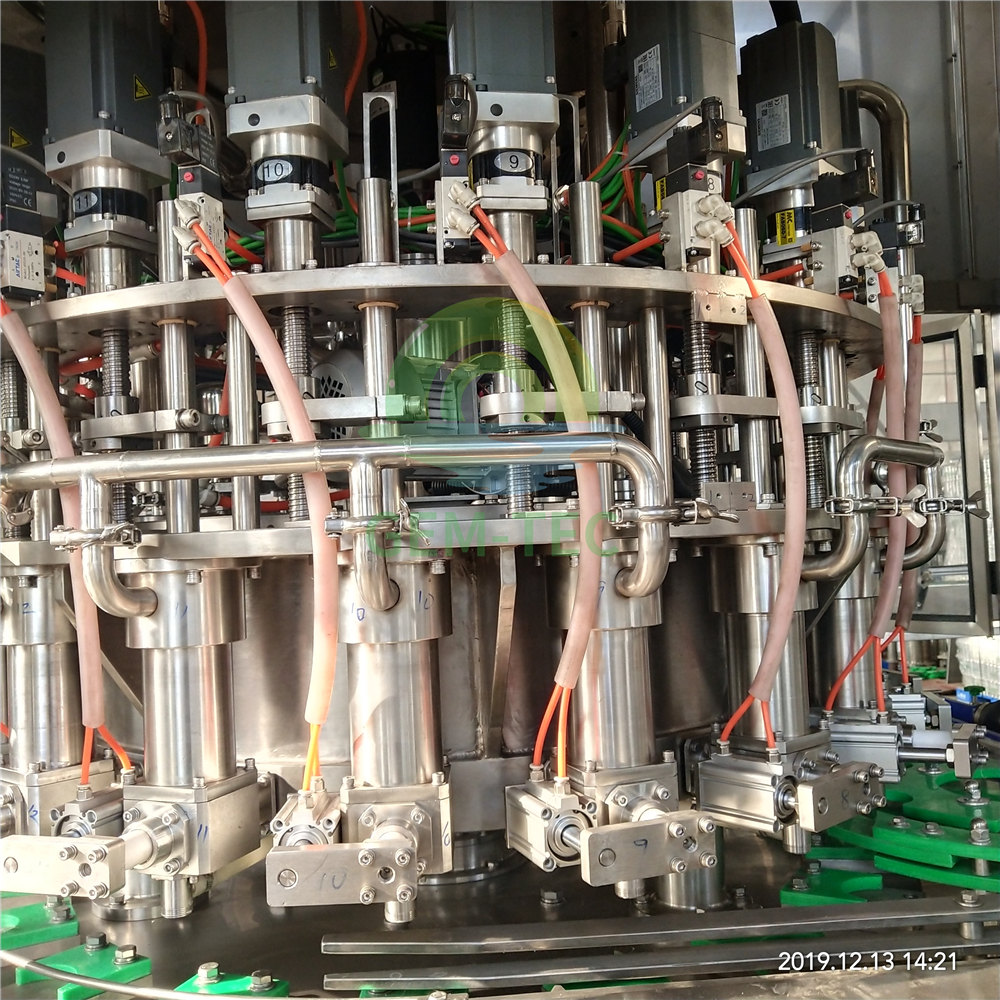

Sharaxaada

gasacadaha leh miisaankiisa fudud, cabbir yar, fudud in la jebiyo, si sahlan loo qaadi karo iyo faa'iidooyin kale, oo ay jecel yihiin inta badan kooxaha macaamiisha.Isla mar ahaantaana, waxay ka samaysan tahay walxo bir ah, sidaas darteed waxay leedahay ilaalin wanaagsan oo iftiin ah.Taas bedelkeeda, dhalooyinka dhalada ah waxay leeyihiin waxqabadka iftiinka lidka ku ah.Haddii dhalooyinka galaaska ah ee cabitaannada ama biirka la dhigo, waxay u baahan yihiin in la dhigo meel qabow si looga fogaado iftiinka qorraxda tooska ah, haddii kale, nolosha shelf ayaa saameyn doonta.Tilmaamahani waxay ka dhigaan gasacadaha gabi ahaanba ka sarreeya dhalooyinka dhalada ee meelaha baakadaha qaarkood.

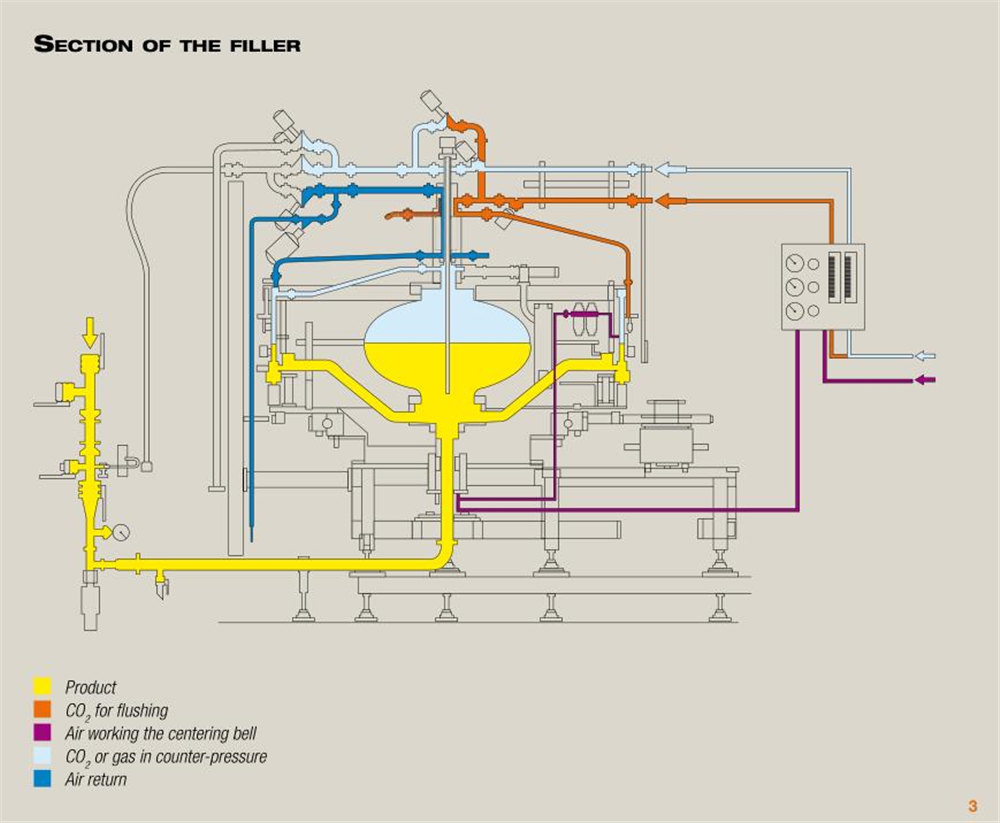

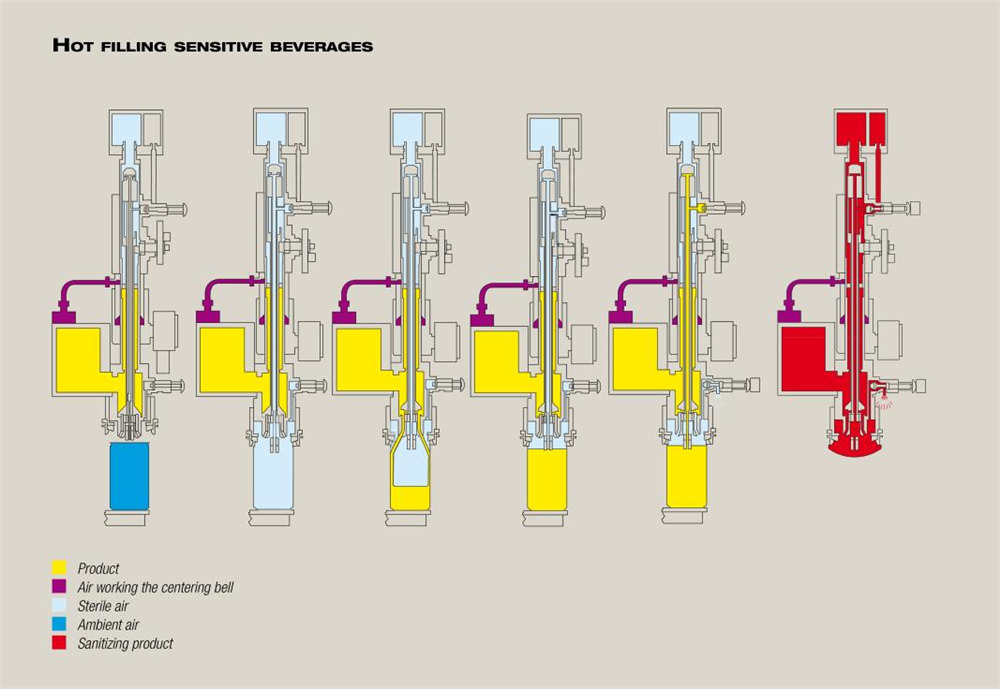

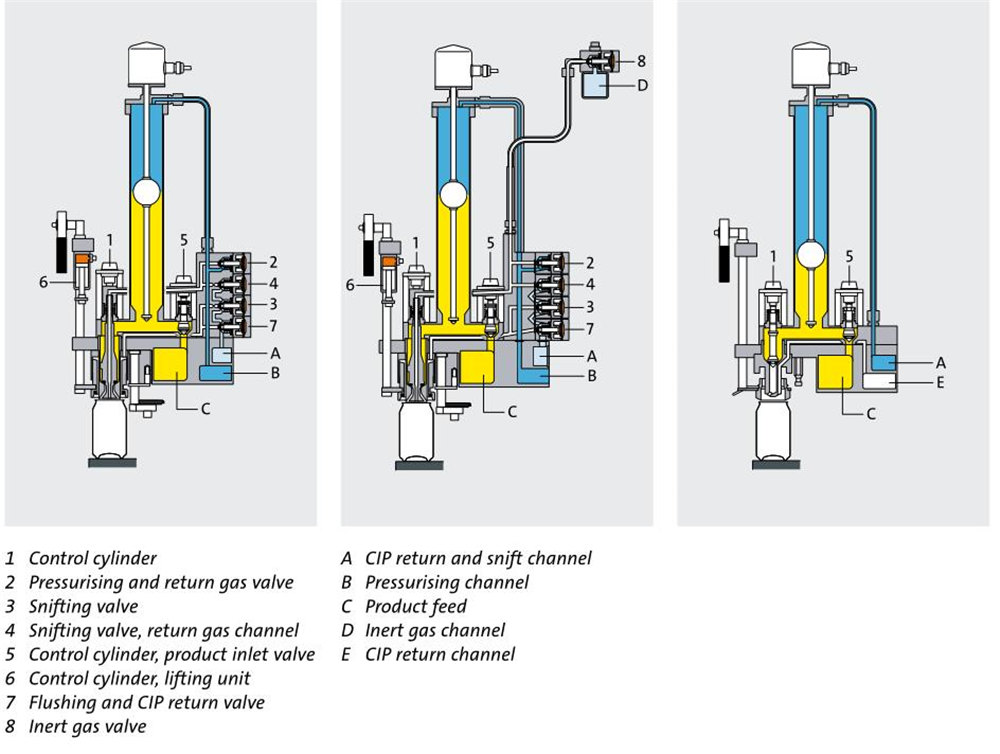

Mashiinka buuxinta GEM-TEC waxaa lagu soo saaray alaabo kala duwan oo maskaxda lagu hayo: biirka, kaarboonka/cabitaanada fudud, casiirka miraha, cabitaanada isboortiga iyo shaaha si loo magacaabo dhowr.Waxaa jira xal buuxin ku habboon badeecad kasta.Tusaale ahaan, qaabka buuxinta kulul ee looga baahan yahay casiirka iyo shaaha, waxaa lagu qalabeeyaa habka dib-u-wareejinta si loo hubiyo in alaabtu leedahay heerkul deggan, xitaa inta lagu jiro wakhtiga hoos u dhaca.Beerka, CSD ee looga baahan yahay habka buuxinta isobaric, oo ku qalabaysan CO2 barokaca, CO2 nadiifinta, cadaadiska, cadaadiska cadaadiska iyo hawlaha kale;Habka buuxinta biyaha ee hodanka ku ah hydrogen, habka buuxinta hoos u buuxinta iyo dib-u-soo-celinta ayaa u qalabaysan sifooyinka cufnaanta hoose ee hydrogen iyo baxsi fudud.Si kastaba ha noqotee nooca cabitaanka, habka buuxinta, waxaan u habeyn karnaa warshadaha hogaaminaya buuxinta tignoolajiyada adiga.

1. Qalabka buuxinta caadiga ah iyadoo la adeegsanayo la isku halleyn karo, mashiinka buuxinta farsamada fudud, marka loo eego qaabeynta alaabada kala duwan ee valve buuxinta u dhigma.Walalka buuxinta saxda ah ee elektiroonigga ah ee miisaanka sarreeya ama korantada buuxinta cabbirka elektiroonigga ah ayaa lagu doortaa iyadoo loo eegayo nooca alaabta.Dhululubo elektaroonik ah oo leh suufka Teflon si loo xakameeyo gaaska nidaamka.Qaar ka mid ah makaanikada iyo dhammaan qalabka elektiroonigga ah ee leh xakamaynta pneumatic ee gacanta dhexe, ma jirto CAM qaadis, habka buuxintu uma baahna inuu qaado gasacadaha.

2. Nidaamka xakamaynta Siemens, oo leh awoodda xakamaynta otomatiga sare, dhammaan qaybaha shaqada ee hawlgalka otomatiga ah, wax hawlgal ah ma jiro ka dib bilawga (Tusaale ahaan: xawaaraha buuxintu wuxuu raacayaa xawaaraha khadka oo dhan, ogaanshaha heerka dareeraha, hagaajinta quudinta, nidaamka sifeynta, iwm.)

3. Gudbinta mishiinku waxay qabataa nashqad qaabaysan, isbedbeddelka soo noqnoqda ee nidaamka xawaaraha stepless, nidaaminta xawaaraha ballaaran.Darawalku waxa uu ku qalabaysan yahay qalab dufan si toos ah u saliidayn kara, kaas oo keeni kara saliid goob kasta oo saliidaynaysa iyadoo loo eegayo baahida wakhtiga iyo tirada, oo leh saliid ku filan, hufnaan sare, buuq yar iyo cimri dheer.Waxa kale oo ay la shaqayn kartaa mishiinka gariiradda si ay u isticmaasho servo wadista kala soocida korantada, ma jirto gudbinta farsamada adag si fudud u fadhiisan karta mishiinka buuxinta iyo isku xidhka mashiinka, gudbinta la isku halayn karo, dayactir fudud.

4. Dhererka walxaha ku jira dhululubada buuxinta waxaa lagu ogaadaa baaritaanka elektiroonigga ah, iyo PLC-ga xiritaanka PID-da ayaa hubiya heerka dareeraha xasilloon iyo buuxin la isku halleyn karo.

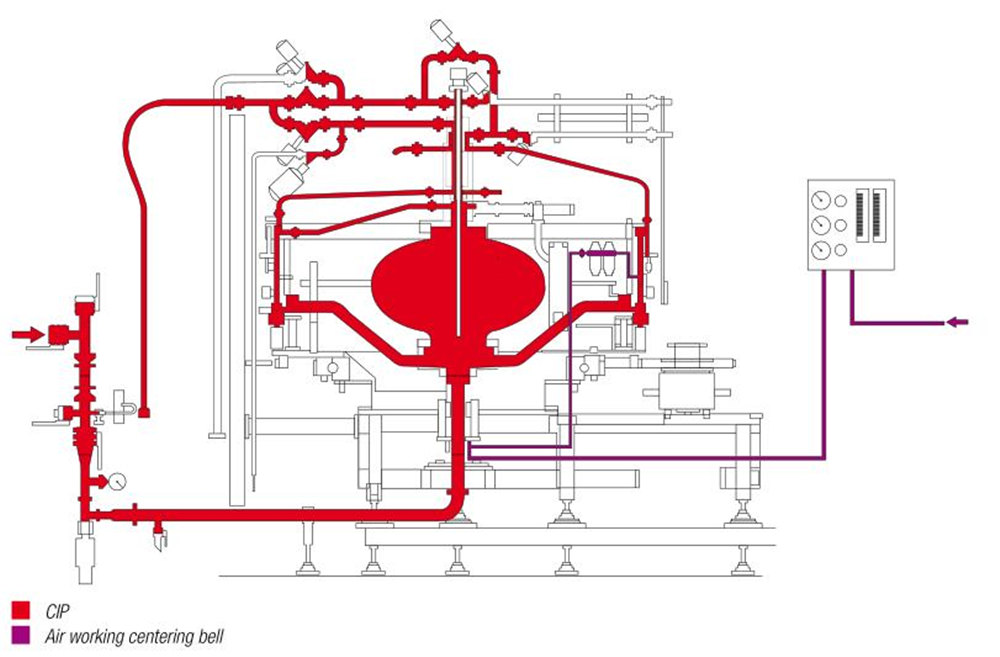

5. Kanaalka walxaha si buuxda ayaa loo nadiifin karaa CIP, iyo goobta shaqada iyo qaybta xiriirka dhalada si toos ah ayaa loo dhaqi karaa, taas oo buuxisa shuruudaha nadaafadda ee buuxinta;Waxaa loo isticmaali karaa iyadoo loo eegayo baahida miiska janjeera ee hal dhinac ah;Koobab been abuur ah oo toos ah oo CIP ah ayaa sidoo kale la heli karaa.

6. Ku habboon noocyada kala duwan iyo moodooyinka mashiinka wax lagu xiro.

Si loo hubiyo dhadhanka aadka u fiican iyo cabitaanka cabitaanka si loo buuxiyo, waa lagama maarmaan in la duubo oo la xiro daboolka daasadaha isla markiiba ka dib buuxinta.Mashiinka wax lagu xiro ee xawaaraha sare leh ee otomaatigga ah waxaa loo isticmaalaa in lagu xiro mashiinnada buuxinta kala duwan ee ka dambeeya khadka wax soo saarka cuntada iyo cabitaanka qasacadaysan.Mabda'a shaqadu waa in kursiga taangiga ee taageerada hoose uu u kaxeeyo jirka taangiga si uu u wareego oo kor u qaado, ka dibna shaabadeynta koowaad iyo labaad waxay u dhaqmaan cidhifka madaxa duubista si isdaba-joog ah, ka dibna iyada oo loo marayo xiridda CAM si loo dhamaystiro ficilka xiritaanka.Waxaa lagu habeyn karaa 2/4/6/8 madax gariiraya, oo leh awood saxan oo xawaaraheeda sare leh ilaa 700-800 gasac daqiiqaddii.Nooc kastaa wuxuu ku qalabaysan yahay qalab ilaalin badan oo badbaado si loo hubiyo waxqabadka labaad ee dib u celinta ee hawlgalka xawaaraha sare.Beddelka nooca haanta waa mid aad u fudud oo degdeg ah.

Tilmaamaha Makaanikada

1. Qaab dhismeedka modulku waa is haysta, dunta iyo dhammaan qaybaha xajinta oo leh sifaynta sahayda saliida tooska ah ee dhexe, oo lagu dhex dhisay sifaynta taayirrada gariiradda.

2. Xakamaynta beddelaha soo noqnoqda, xawaaraha wax soo saarka ayaa si xor ah loo hagaajin karaa;Tiknoolajiyada mootada servo waxaa loo dooran karaa si loo xaqiijiyo kala-soocidda iyo gudbinta isku-dhafka ah ee mashiinka faleebada iyo mashiinka duubista si loo yareeyo qaybaha gudbinta farsamada.

3. Kursiga rullaluistemadka gariiradda daboolaya waa ay fududahay in la isku hagaajiyo, rullaluistemadka xidhidhiyaha gariiradda iyadoo la isticmaalayo titanium nitride (TIN) daaweynta daahan dusha.

4. Qalabka daboolka daboolka caadiga ah ee taangiga (koofida daboolka), waxay yarayn kartaa cadaadiska ururinta jeexdin ee quudinta daboolka.

5. Mashiinku wuxuu ku qalabaysan yahay qalabyo badbaado oo badan oo isku xiran si loo hubiyo badbaadada mashiinka-mashiinka.

6. Dusha xidhiidhka ee u dhexeeya giraangiraha xiddigta wareejinta iyo jidhka taangiga waxa lagu daaweeyaa dahaadh koromium ah si looga hortago in jidhka taangiga la xoqo.

7. HMI (shaashadda taabashada), xakamaynta mashiinka dhabta ah, nooca fashilka iyo macluumaadka wax soo saarka oo dhameystiran.

8. Gaashaanka dibadda ee jirka ee birta ah iyo daaqadaha muraayadda ee adag.

9. Naqshad nadaafadeed oo qumman, fududahay in la nadiifiyo.

10. (Ikhtiyaar) Qalabka kor u qaadida madaxa gariiradda korontada.

11. (Ikhtiyaar ah) CO2 iyo qalabka uumiga nadiifiyo ee daboolka haanta hoostiisa.

Halbeegga

| Halbeegga farsamada: cabitaanka cabitaanka ayaa buuxin kara mishiinada | |||||

| Qaabka | JH-CF12-1 | JH-CF18-4 | JH-CF24-4 | JH-CF30-6 | JH-CF40-8 |

| Awoodda ( gasacadaha/saacadaha) | 2000 | 8000 | 12000 | 15000 | 20000 |

| Weel ku habboon | Qasacad Aluminium / Daasacad / qasac caag ah | ||||

| Dhexroorka kara | Dia50 ~ dia99mm | ||||

| Dhererka kara (mm) | 70-133mm | ||||

| Compressor hawo | Buuxinta isobaric / buuxinta cadaadiska caadiga ah | ||||

| Codsiga | Mashiinka Buuxinta Cabitaanka | ||||

| Wadarta awooda (kw) | 2.4kw | 4.4kw | 5.2kw | 6.2kw | 7.2kw |

| cabbirada guud | 2.5*1.9m | 2.8*1.9m | 3.2*2.15m | 3.5*2.5m | 3.8*2.8m |

| Dhererka | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m |

| Miisaanka (kg) | 2500kg | 3200kg | 4000kg | 4500kg | 6500kg |

Qaab dhismeedka