Mishiinka Buuxinta Khamriga Dhalada ah ee Tooska ah/Whiski

Sharaxaada

Ruuxu waa cabitaano aalkolo leh oo la dhalaaliyay iyada oo aan halsano.Ruuxa la jeexjeexay waxay u muuqdaan inay leeyihiin boqolkiiba celcelis ahaan khamriga mugga, oo u dhexeeya 20% ilaa 90% ABV.Si loo sameeyo ruux xoog leh, alaabta ceeriin sida miraha, baradhada iyo badarka ayaa loo isticmaalaa habka nadiifinta.Cabitaanada khamriga la miiray ee caanka ah waa whiskey, gin iyo vodka.Suuqa cabitaanka khamriga ee caalamiga ah ayaa la filayaa inuu gaaro ilaa $2 trillion marka la gaaro 2025, daraasadda ayaa tiri.Ruuxyadu waxay ku xisaabtami doonaan saddex meelood meel wadarta suuqa.Muuqata, ruuxyadu waxay ku xisaabtamaan qayb wayn oo suuqa ah.

Markasta oo uu sareeyo qiimaha badeecada, waa inta badan khasaaraha ka dhalan doona cabirka buuxinta aan saxda ahayn.Si looga fogaado khasaarahan oo kale, GEM-TEC mashiinka buuxinta khamriga waxay si adag u raacdaa shuruudaha nidaamka buuxinta saxda ah.Haddii badeeco badan lagu shubo weelka, nidaamku si toos ah ayuu u saxayaa heerka dareeraha.Alaabooyinka ay ku jiraan aalkolada sare waxay sidoo kale u baahan yihiin daaweyn aan qarxin habka dhalada.Nidaamka korantada ee mishiinkeenu wuxuu qaataa alaabada aan qarxin si loo baabi'iyo khataraha badbaadada.Xalalkayagu waa ay fududahay in la nadiifiyo si alaabtaadu u buuxiso dhammaan shuruudaha nadaafadda.

Mabda'a shaqada ee buuxinta khamriga cad weelka dhalada ah

Mashiinka buuxinta ruuxyada ayaa guud ahaan qaata habka buuxinta faakuumka.Ruuxyada lagu duray dhalada ayaa lagu kala firdhiyaa gidaarka gudaha ee dhalada dalladda weecinta, hawada dhalada ku jirtana waxaa nuuga nidaamka faakuumka iyadoo la sii marayo tuubada soo laabashada.Habka gaarka ah waa sida soo socota: dhalada ayaa kor loogu qaadayaa xagga hoose ee waalka buuxinta waxaana la furay tuubada buuxinta.Buuxinta ayaa bilaabanaysa.Marka heerka dareeraha khamriga ee dhalada ku jira uu ka sarreeyo tuubada soo celinta, tuubada waa la xirayaa.Heerka dareeraha ayaa markaa la saxayaa faakuumka: alaabta xad-dhaafka ah ayaa dib loogu nuugaa dhululubada buuxinta iyada oo la sii marayo tuubada gaaban.Sababtoo ah shaqada furitaanka iyo xiritaanka waalka waxaa gacanta ku haya dhalada, sidaas darteed: "dhalo ma leh, habka buuxinta ma jiro".

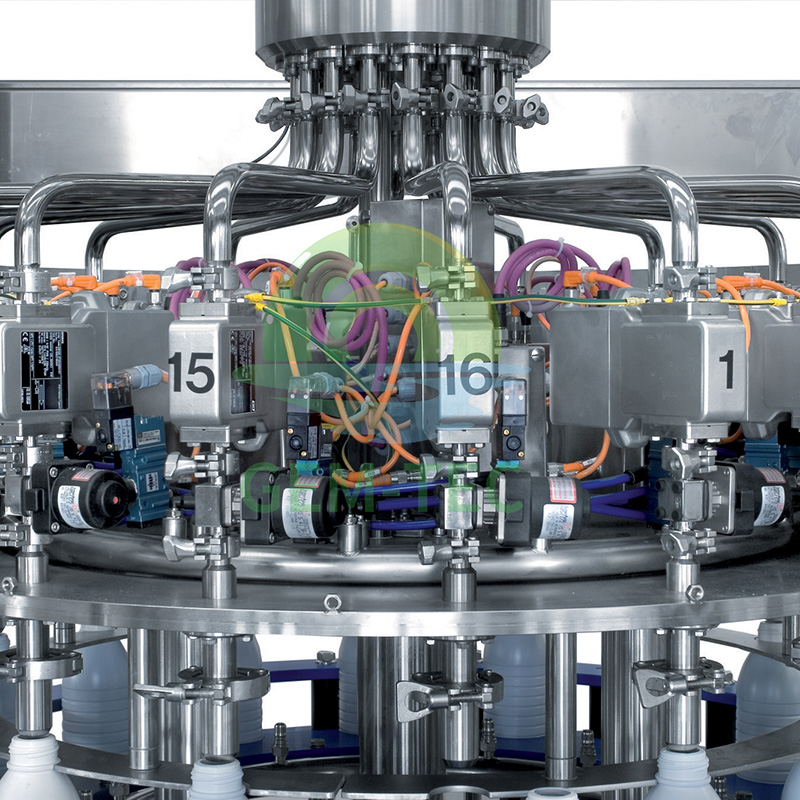

Dabcan, buuxinta khamriga GEM-TEC waxay sidoo kale isticmaali kartaa nidaamka buuxinta kubbadda sabbaynaysa ee elektiroonigga ah, buuxinta saxnaanta waa mid sare, dhakhso leh.Waalka elektiroonigga ah wuxuu qaataa cabbiraadda waqtiga-dhabta ah iyo tignoolajiyada kontoroolka, tignoolajiyada magdhawga hawlgalka PLC iyo tignoolajiyada xakamaynta qulqulka doorsooma si ay ugu riixdo saxnaanta buuxinta iyo xawaaraha buuxinta dherer cusub.Habka buuxintu waxa kale oo uu la mid yahay qaab-dhismeedka waalka ee saddex-geesoodka ah.Ruuxa ayaa marka hore lagu duraa foosto cabbiraadda elegtarooniga ah.Ka dib marka la gaaro awoodda la dejiyay, ruuxyada ku jira foosto cabbirka ayaa markaa lagu duraa dhalada.

Astaamaha

Tilmaamaha waxqabadka waalka makaanikada

1. Hubi heerka ugu wanaagsan ee khaladaadka buuxinta iyo khasaaraha khamriga

2. Si sax ah u go'aami dhererka heerka buuxinta iyada oo loo marayo hagaajinta faakuumka iyo dhererka tuubada soo celinta

3. Waalka buuxinta makaanikada gacanta lagu hayo, wuxuu awoodaa +/- 4 mm beddelka dhererka buuxinta

4. Waalka buuxinta ikhtiyaariga ah oo leh ama aan lahayn shaqada CIP

5. Weelka bakhaarku waxa uu ku yaalaa xaalad faaruq ah oo hoose, iyada oo aan la buuxin dhibco

6. Nidaamka xakamaynta ee Siemens, oo leh awoodda xakamaynta otomatiga sare, dhammaan qaybaha shaqada ee hawlgalka otomatiga ah, ma shaqeynayo ka dib bilawga

7. Gudbinta mishiinku waxay qabataa naqshad qaabaysan, jaangooyooyin xawli-la'aan inta jeer ee isbeddelka, kala duwanaanshaha xawaaraha ballaaran.Darawalku waxa uu ku qalabaysan yahay qalab dufan si toos ah u saliidayn kara, kaas oo keeni kara saliid goob kasta oo saliidaynaysa iyadoo loo eegayo baahida wakhtiga iyo tirada, oo leh saliid ku filan, hufnaan sare, buuq yar iyo cimri dheer.

8. Dhererka walxaha ku jira dhululubada buuxinta waxaa lagu ogaadaa baaritaanka elektaroonigga ah.PLC kontoroolka loop-xiran ee PID wuxuu xaqiijiyaa heerka dareeraha xasilloon iyo buuxin la isku halayn karo.

9. Hababka kala duwan ee wax lagu xidho waa ikhtiyaari (sida: daboolka aluminium, koofiyadda taajka, qanjidhada qaabab kala duwan, iwm.)

10. Kanaalka walxaha si buuxda ayaa loo nadiifin karaa CIP, iyo goobta shaqada iyo qaybta xiriirka dhalada si toos ah ayaa loo dhaqi karaa, taas oo buuxinaysa shuruudaha nadaafadda ee buuxinta;Waxaa loo isticmaali karaa iyadoo loo eegayo baahida miiska janjeera ee hal dhinac ah;Koobab been abuur ah oo toos ah oo CIP ah ayaa sidoo kale la heli karaa.

Marka lagu daro sifooyinka kor ku xusan, waalka elektaroonigga ah wuxuu kaloo leeyahay sifooyinka soo socda:

● Ma lumin, fududahay in la isku hagaajiyo: dhalada ku jirta habka buuxinta iyada oo aan dhaqdhaqaaqa kor loo qaadin, ma la xiriirto jirka waalka, ku dhawaad ma jiraan qaybo xiran;Markaad hagaajinayso awoodda, kaliya waxaad u baahan tahay inaad taabato shaashadda taabashada si aad u bedesho xuduudaha si aad u sameyso hagaajin aan tallaabo lahayn, waxaad sidoo kale ku kaydin kartaa cabbirrada kala duwan ee khamriga nidaamka caanaha.Markaad bedesho khamriga, waxaad u baahan tahay oo kaliya inaad wacdo noocyada kala duwan ee shaashadda taabashada si aad si toos ah u buuxiso, si weyn u wanaajiso waxtarka wax soo saarka.

● Habaynta sare, isku halaynta sare: marka la barbar dhigo nidaamka qalabka farsamada, qaybo badan oo elektaroonig ah ayaa ka qaybqaata habka buuxinta, xakamaynta nidaamku waa mid sax ah, ogaanshaha xasaasiga ah.

● Ma jiro dareere xiiqsan, ma jiro wax diiqaya: tuubada buuxinta waxay qabataa kanaalka qoyaanka, khamriga ma fududa in la buufiyo qulqulka, meel u dhow afka dhalada marka heerka dareeraha dareeruhu hoos u dhaco, tiirka dareeraha ayaa noqda mid fiican oo si tartiib ah loogu durayo dhalada, tirtir dareeraha xumbo, xidhitaanka gadaasha ka dib buuxinta, ma da'.

Qiyaasta Farsamada

| Nooca mashiinka | madax buuxin | Dhererka dhalada | Dhexroor dhalada | Wax soo saarka wax soo saarka | Buuxinta saxnaanta | Baaxadda buuxinta | Cadaadiska hawada oo cadaadissan |

| JH-FF18 | 18 | 100-300 | 50-100 | ≤6600 (b/sacaddii) | ± 1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 24 | 24 | 100-300 | 50-100 | ≤9000 (b/h) | ± 1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 36 | 36 | 100-300 | 50-100 | ≤14000 (b/h) | ± 1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 48 | 48 | 100-300 | 50-100 | ≤18000 (b/h) | ± 1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 60 | 60 | 100-300 | 50-100 | ≤22000 (b/h) | ± 1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 72 | 72 | 100-300 | 50-100 | ≤26000 (b/h) | ± 1.0ml/500ml | 40-600ml | 0.4-0.5MPa |