Mashiinka Buuxinta Cabitaanada Jilicsan ee Kaarboonaysan

Video

Sharaxaada

Cabbitaannada fudud ee Kaarboonka ah (CSD) ayaa weli ah mid ka mid ah qaybaha cabitaannada ugu qiimaha badan adduunka, oo ay ku xigaan oo keliya biyaha caagagga ah ee cabbirka iibka.Adduunkeedu waa mid midab leh oo dhalaalaya;Iyada oo baahida macaamilku ay si joogto ah isu beddesho, wax-soo-saarka CSD wuxuu u baahan yahay dabacsanaan si loo gaaro mugga ugu sarreeya si loo soo bandhigo badeecadaha cusub ee CSD si dhakhso ah oo hufan.Baro xalalkayaga CSD ee dhamaystiran iyo sida aan kuugu caawin karno inaad kor ugu qaaddo khadkaaga wax soo saarka ee CSD si aad u hesho waxqabadka ugu fiican iyo dabacsanaanta adigoo yareynaya kharashka isticmaalkaaga wax soo saarka.

JH-YF Mashiinka buuxinta cabitaannada fudud ee kaarboonka leh ayaa ku habboon dhammaan noocyada cabitaannada fudud ee PET/ galaaska.Tignoolajiyada buuxinta isku-kalsoonida isobaric (ka-hortagga-cadaadiska) ayaa la qaatay.Tiknoolajiyadeena buuxinta waxay ka caawin kartaa noocyada ugu sarreeya inay kordhiyaan wax soo saarka dhalada si dhaqaale iyo degdeg ah.Iska yaree isticmaalka co2, yaree heerka isticmaalka cabitaanka.

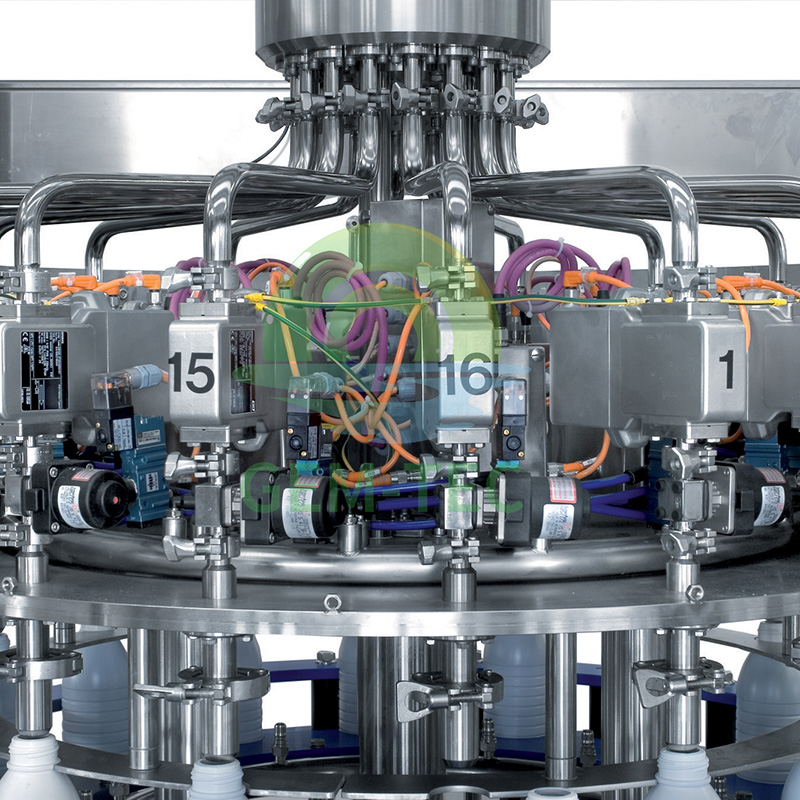

Moodooyinka caadiga ah waxay adeegsadaan kuwo xasiloon oo sahlan in la nadiifiyo valves buuxinta farsamada, oo ay ku jiraan furayaasha furan iyo kuwa dhow, CO2 nadiifinta, CO2 sicir bararka, cadaadiska buuxinta ka dib waxaa dhammaan gacanta ku haya kamaradaha farsamada.

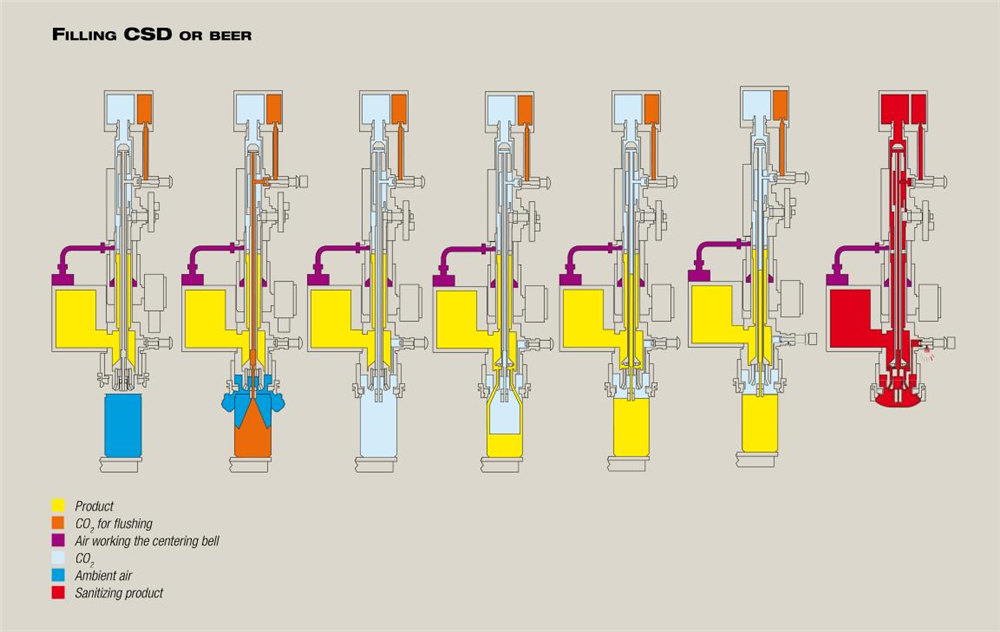

Buuxinta Habka Hawlgalka

Ku bilow adigoo si adag u cadaadinaya afka weelka PET/ galaaska oo cadaadinaya gudaha dhalada.Marka cadaadiska firaaqada ah ee dhululubada iyo cadaadiska gudaha dhalada ay isku mid yihiin, guga ayaa furi doona waalka, habka buuxinta ayaa isla markiiba bilaabmi doona;Buuxinta ayaa sii socota ilaa heerka dareeraha uu gaaro dhamaadka hoose ee tuubada soo noqoshada, buuxintana waa la joojiyaa.Marxaladda dejinta ka dib, tuubada ayaa xirta;Marka cadaadiska dhuunta dhalooyinka la saaro, buuxinta waa la dhammeeyaa.

Tilmaamaha Qaab-dhismeedka Farsamada

1. Buuxinta waalka buuxinta waxay qabataa waalka buuxinta farsamada saxda ah.(Ikhtiyaarka waalka elegtarooniga ah ee heerka waalka/waalka mugga korantada)

2. Biyo shubashada ama buuxinta, dhibaatooyinka tayada dhalada ee ay sababto dilaaca dhalada awgeed, tuubada buuxinta si toos ah ayaa loo xidhay, waxaana jira dhalada jaban oo si toos ah u nadiifinaysa.

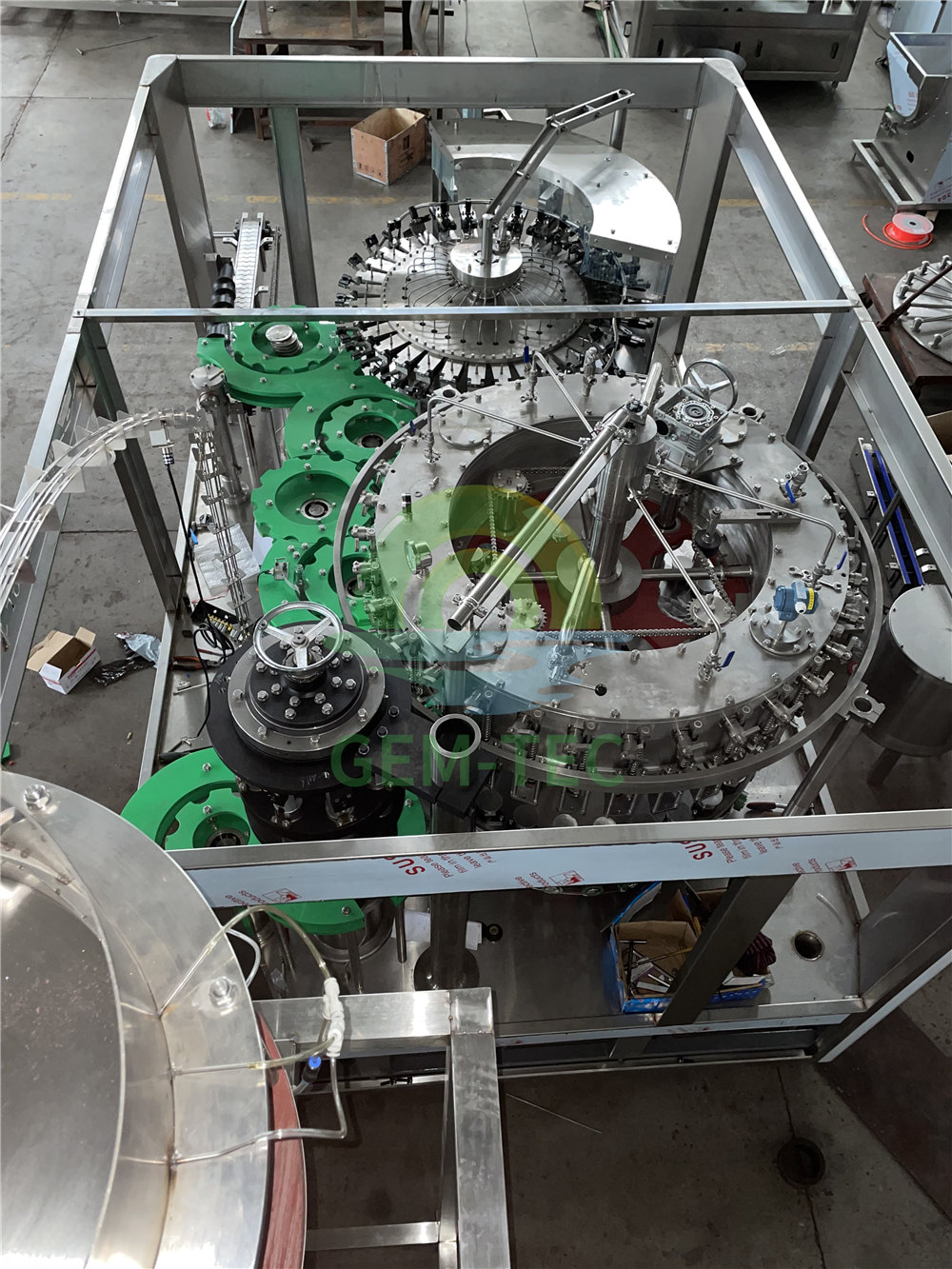

3. Gudbinta mishiinku waxay qabataa nashqad qaabaysan, isbedbeddelka soo noqnoqda ee nidaamka xawaaraha stepless, nidaaminta xawaaraha ballaaran.Darawalku waxa uu ku qalabaysan yahay qalab dufan si toos ah u saliidayn kara, kaas oo keeni kara saliid goob kasta oo saliidaynaysa iyadoo loo eegayo baahida wakhtiga iyo tirada, oo leh saliid ku filan, hufnaan sare, buuq yar iyo cimri dheer.

4. Cadaadiska dambe ee walxaha ku jira dhululubada buuxinta si toos ah ayaa loo xakameyn karaa, xaaladaheeda shaqo iyo qiyaasaha waxaa lagu soo bandhigi karaa golaha xakamaynta.

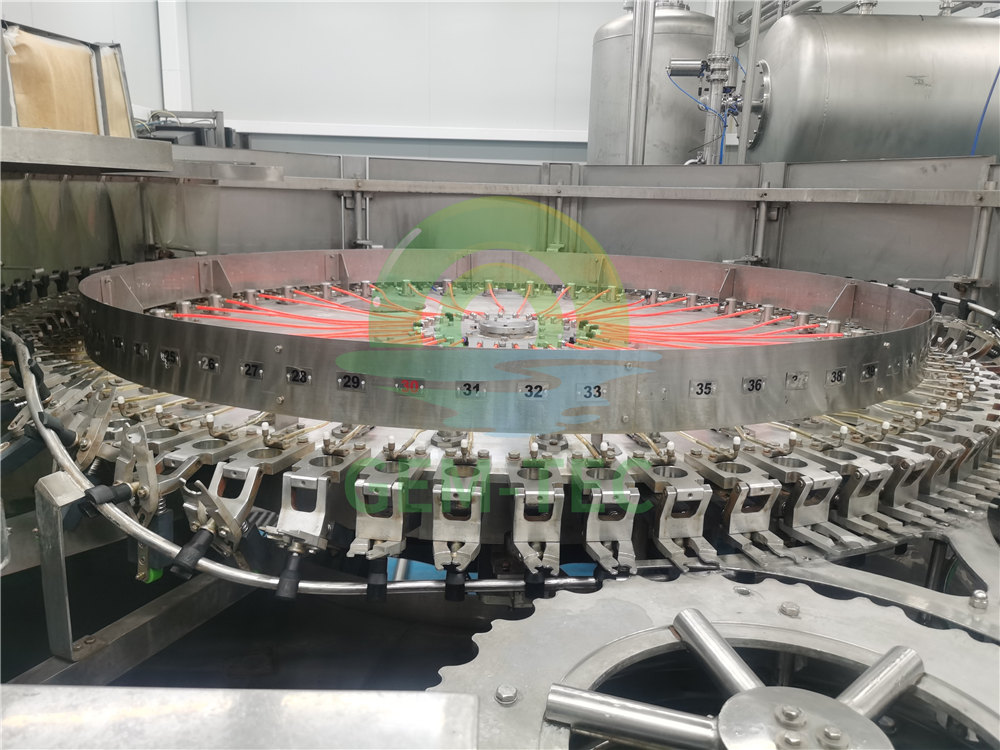

5. Dhererka walxaha ku jira dhululubada buuxinta waxaa lagu ogaadaa baaritaanka elektaroonigga ah.PLC kontoroolka loop-xiran ee PID wuxuu xaqiijiyaa heerka dareeraha xasilloon iyo buuxin la isku halayn karo.

6. Dhererka dhululubada buuxinta iyo giraanta xakamaynta ayaa la hagaajin karaa si ay ugu habboonaato buuxinta weelasha cabbirrada kala duwan ee cabbirka naqshadeynta.

7. Isticmaalka dhammaan daboolka daboolka daboolka ah, daboolka daboolka, daboolka, galka gudbinta daboolka waa mid la isku halleyn karo, hawlgalka daboolka ma fududa in la beddelo, daboolku waa weyn yahay oo aan la daboolin,

8. Qanjirku waa la isku halleyn karaa;Oo waxay leedahay shaqo dejin toos ah, hoos u dhig heerka dhalada jaban.

9. Nidaamka xakamaynta Siemens, oo leh awoodda xakamaynta otomatiga sare, dhammaan qaybaha shaqada ee hawlgalka otomatiga ah, hawlgal la'aan ka dib bilawga (sida: xawaaraha buuxinta waxay raacaan xawaaraha xariiqda oo dhan, heerka dareeraha ogaanshaha, xakamaynta dareeraha dareeraha, cadaadiska xumbo, nidaamka sifeynta. , habka gudbinta daboolka)

10. Kanaalka walxaha si buuxda ayaa loo nadiifin karaa CIP, iyo goobta shaqada iyo qaybta xiriirka dhalada si toos ah ayaa loo dhaqi karaa, taas oo buuxinaysa shuruudaha nadaafadda ee buuxinta;Waxaa loo isticmaali karaa iyadoo loo eegayo baahida miiska janjeera ee hal dhinac ah;

11. Hababka wax lagu xidho ee kala duwan (sida: daboolka taajka, daboolka jiidida, daboolka ka hortagga tuugada ee birta ama caaga ah, iwm.)

Marka loo eego shuruudaha isticmaalayaasha kala duwan iyo alaabada kala duwan, buuxinta valve sidoo kale waxay isticmaali kartaa buuxinta elektaroonigga ah.Habkan buuxinta ayaa koontaroolaya furitaanka iyo xidhitaanka valve biirka, faakiyuumaynta, cadaadiska cadaadiska qiiqa iyo ficilada kale ayaa ah xakamaynta sambabada, iyo heerka qulqulka buuxinta si habboon ayaa loo hagaajin karaa.Qaabdhismeedku waa mid aad u fudud, la isku halleyn karo oo sahlan in la ilaaliyo.Waxa kale oo aad habayn kartaa shaqada CIP si toos ah u socota, nadiifinta koobabka been abuurka ah si otomaatig ah ayey u kortaa, hawl gacanta ah looma baahna.Macaamiisha u baahan mugga buuxinta saxda ah, waalka buuxinta tirada elektiroonigga ah ayaa loo isticmaali karaa in lagu beddelo awoodda.Ilaa inta xawaaraha buuxinta lagu hagaajinayo HMI, beddelaad sax ah ayaa la gaari karaa.

Tilmaamaha Farsamada

| nooca | Awoodda wax-soo-saarka (BPH) | Dhexroor goobaabin | cabbirka | |

| JH-PF14-12-5 | 1500-2000/ (500ml) | Φ600 | ||

| JH-PF24-18-6 | 2500-3500 | Φ720 | ||

| JH-PF32-24-8 | 3500-4500 | Φ960 | ||

| JH-PF40-32-10 | 7000-8000 | Φ1120 | ||

| JH-PF50-40-12 | 10000-12000 | Φ1400 | ||

| JH-PF60-50-15 | 13000-16000 | Φ1500 |