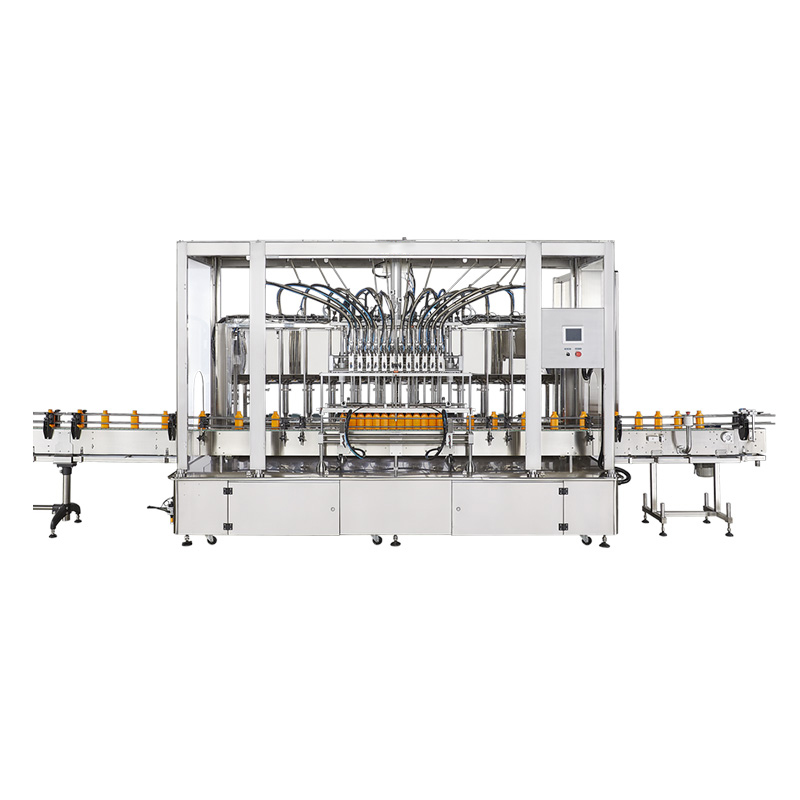

Mishiinka Buuxinta Tooska ah ee Yar yar

Video

Sharaxaada

Mashiinnada buuxinta tooska ah ayaa ah kuwa ugu badan oo buuxin kara ku dhawaad dareere kasta.Waxay si gaar ah ugu habboon tahay buuxinta shuruudaha wax soo saarka gudaha 2000BPH.Marka loo eego shuruudaha buuxinta alaabada kala duwan, waxaan siinaa isticmaaleyaasha noocyo kala duwan oo mashiinnada buuxinta tooska ah.Loo isticmaalo cuntada iyo cabitaanka (biyaha, biirka, cabbitaannada kaarboonaysan, casiirka khudradda, cabitaannada isboortiga, rooxaanta, iwm.), dawooyinka, sunta cayayaanka, warshadaynta, waxyaalaha la isku qurxiyo, musqulaha, daryeelka shakhsi ahaaneed, kiimikooyinka, batroolka iyo warshado kale.Codsiyada ballaaran ee mashiinka buuxinta tooska ah ayaa go'aaminaya habab buuxintiisa sidoo kale waa kala duwan yihiin, sida saliingaha piston, mitirka socodka, faakuumka, bamka gear, buuxinta culeyska iyo wixii la mid ah.Dabcan, waxaa jira siyaabo badan oo loo daboolo, sida: qanjidhada, koofiyadda.LIDS ku habboon waxay noqon kartaa LIDS caag ah, LIDS taaj, aluminium LIDS, madaxa bamka LIDS, iwm.

Hababka buuxinta kala duwan ee mashiinka buuxinta tooska ah:

Buuxinta bisinka mugga ee Servo

Buuxinta piston Volumetric waa nooca buuxinta inta badan la isticmaalo oo sax ah.Waxay buuxin kartaa noocyo kala duwan oo ah badeecooyin viscous ah, badeecooyin semi-viscous ah iyo alaabooyin waaweyn oo granule ah.Buuxinta piston Volumetric waxaa la isticmaalaa marka xaddi badeecad ah loo baahan yahay in lagu buuxiyo weelka.Isticmaalayaal badan oo sax ah oo dabacsan, habka buuxinta piston-ka ee adeegaha ayaa diyaar ah.Hawlwadeenku wuxuu hagaajiyaa mugga buuxinta iyada oo loo marayo interface interface, iyo shaqada kaydinta caanaha waxay kuu ogolaaneysaa inaad abuurto, nuqul ka sameyso oo aad wacdo cuntooyinka.

Buuxinta mitirka socodka

Habka buuxinta dareeraha dareeraha ah ayaa bixiya habka ugu wanaagsan ee lagu cabbirayo socodka dareeraha.Si sax ah u ogaan kara socodka dareeraha dhex socda.Ma jiro tignoolajiyada buuxinta kale oo bixiya sifooyin horumarsan iyo faa'iidooyin.Nidaamyada buuxinta Flowmeterka waxay bixiyaan waxtarka qiimaha weyn iyo dabacsanaan aad u sarreeya ee hababka buuxinta saxda ah.

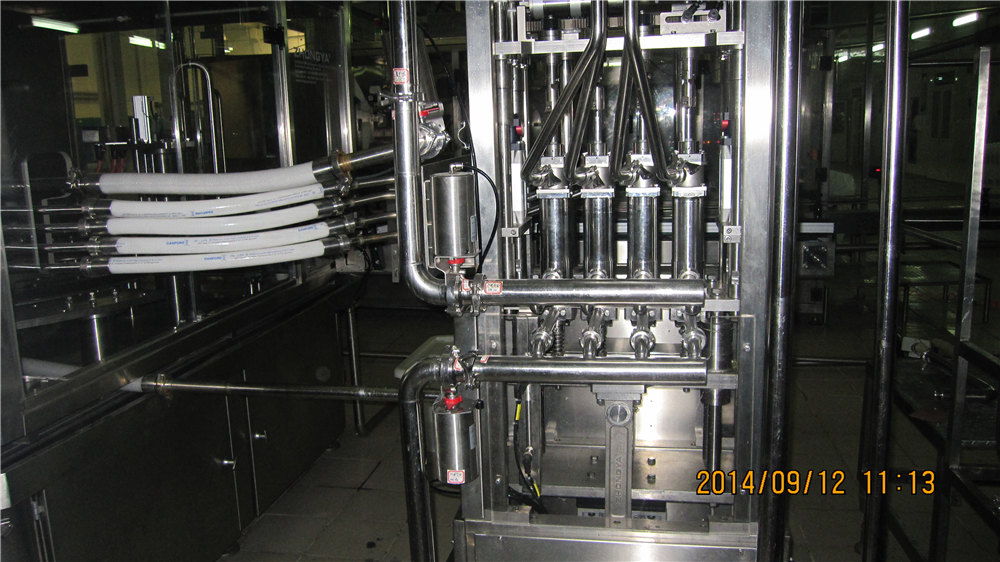

Buuxinta matoorka Gear

Buuxinta bamka Gear wuxuu bixiyaa xal dabacsanaan badan oo codsiyo kala duwan ah.Sida, saliid, kareem, lotion iyo shaambo lagu buuxiyo.Sababtoo ah cadaadiska togan iyo shaqada is-xakamaynta ee xirmooyinka bamka, waxay buuxin kartaa mugga yar yar ilaa mugga weyn (10ml-11000ml) ee walxaha, beddelo qadarka buuxinta iyada oo aan wax habayn ama qalab farsamo, hawlgalka.

Buuxinta bamka Peristaltic

Bamka Peristaltic waa sahlan tahay in la nadiifiyo, ku habboon buuxinta dareeraha nadiifka ah ama wasakhaysan, walxaha iyo qaybaha matoorka ma dhici doonaan wasakhayn isdhaafsan.Bamka waa sahlan tahay in la nadiifiyo lagana dilo jeermiska sababtoo ah qaybta kaliya ee bamka taabta walxaha la buuxinayo waa gudaha tuubada.

Fakuumka iyo buuxinta cuf-isjiidadka

Mashiinnada buuxinta dhalada vacuum waxay ku habboon yihiin buuxinta walxaha mawjadaha hoose iyo kuwa dhexdhexaadka ah.Nuxurka habkan buuxinta ayaa ah buuxinta heerka go'an, taas oo ah, heerka dareeraha ee weel kasta wuxuu ku yaalaa isla boos siman.Iyadoo aan loo eegin xajmiga weelka, waxaa lagu buuxin karaa heer go'an.

Buuxinta miisaanka

Habka buuxinta ayaa ku habboon buuxinta dareeraha mugga weyn.Tani waxay bixisaa xal loogu talagalay dareere kala duwan oo u baahan qaybinta miisaanka saxda ah.Mashiinkan, culeyska waxaa xakameynaya dareeraha miisaamaya oo leh saxsanaan sare, buuxintuna waxay dhammaanaysaa marka miisaanka la dejiyo la ogaado.

Tilmaamaha Mashiinka

Mashiinka buuxinta dareeraha tooska ah Tilmaamaha:

1. Waxay isticmaali kartaa noocyo kala duwan oo ka mid ah weelka daadinta warbaahinta, wakhtiga daadinta waxaa lagu hagaajin karaa sida la rabo, dabcan, waxay sidoo kale isticmaali kartaa weelka gaaska qulqulaya cadaadiska sare.

2. Buuxinta farsamada caadiga ah ee buuxinta soo noqnoqda saxnaanta buuxinta ± 0.5 ~ 1%;Xaqiijinta buuxinta cabbirka elegtarooniga ah<± 0.5%, hagaaji mugga buuxinta adiga oo aan joojin mishiinka.

3. Way ku habboon tahay oo dhakhso badan tahay in la beddelo nooca dhalada.

4. Marka loo eego walxo kala duwan si loo doorto hababka buuxinta kala duwan: syringe piston servo, mitir socodka, vacuum, baakaynta miisaanka, tignoolajiyada buuxinta bamka gear.

5. Duubka buuxinta waxaa lagu dejin karaa inuu si la mid ah u kaco heerka dareeraha ee habka buuxinta si loo yareeyo xumbo-xumada dareeraha xumbo.

6. Mashiinka si toos ah u furan / xidhidh, marka dhalada ku jirta suunka quudinta si toos ah u bilowdo, dhalada si toos ah uma joogsato.Dhalo ma jirto, ma buuxsanto.

7. HMI-waqtiga dhabta ah ee soo bandhigida xaaladda hadda jirta iyo macluumaadka khaladaadka kala duwan, nalka fashilka isku dhafan iyo alaarmiga, si loo ogeysiiyo hawlwadeenka khaladaadka wax soo saarka.

8. Kanaalka maaddadu way fududahay CIP, miiska mashiinka waa sahlan tahay in la dhaqo.

9. Buuxinta ka dib, qoorta iyo garabka dhalada ayaa 100% ka xoroobay qulqulka/dhicibka.

10. Hababka wax lagu xidho ee kala duwan (sida: qanjidhada balaastikada, koofiyada caagagga ah, iwm.)

11. Marka loo eego shuruudaha alaabada kala duwan iyo xawaaraha buuxinta ee kala duwan, buuxinta lambarka madaxa iyo nooca xidhitaanka ayaa loo habeyn karaa marka la doono.

Halbeegga

| Maya | Mashiinka buuxinta dareeraha tooska ah | warshadaha codsiga |

| 1 | 4/6/8/10/12/ servo piston buuxinta mashiinka | Condiments, saliid, kiimikooyinka maalinlaha ah, biyaha, cabitaannada, iwm |

| 2 | 4/6/8/10/12 / mashiinka buuxinta cuf-isjiidadka | Condiments, biyaha, khamriga, iwm |

| 3 | 4/6/8/10/12/ mashiinka buuxinta bamka gear | saliid, sahay kiimiko maalinle ah, kareem, dareere viscosity sare leh |

| 4 | 4/6/8/10/12 / Mashiinka buuxinta bamka Peristaltic | saliid, sahay kiimikaad maalinle ah, waxyaabaha caanaha laga sameeyo, dareere viscosity sare leh |

| 5 | 4/6/8/10/12 / mashiinka buuxinta dareeraha | Condiments, saliid, sahay kiimiko maalinle ah, biyo, cabitaan iyo wixii la mid ah |